Introduction

Construction projects often need to make holes in existing structures. Stitch drilling is a useful technique for this job. It has become popular among builders for creating openings in walls and floors. This method helps contractors and project managers make holes of different sizes while keeping the building strong.

Diamond stitch drilling has improved a lot in recent years. It gives construction workers better ways to modify buildings. Understanding how it works, what equipment you need, and how much it costs will help project managers do better work.

This article explains what stitch drilling is, how it’s used, what equipment you need, and why it might save you money compared to other methods.

What is Stitch Drilling and How Does it Work?

Basic Definition

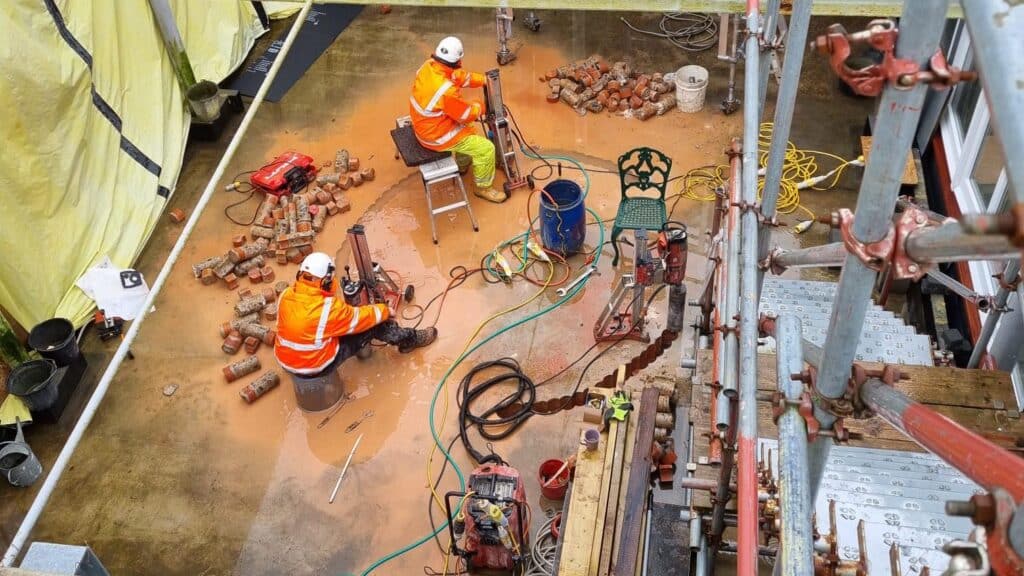

Stitch drilling (also called diamond stitch drilling) uses special drill bits coated with diamonds to make a series of overlapping holes. These holes follow a pattern. Together, they create a continuous cut line. This allows workers to remove concrete or other materials to make openings of any size or shape.

The process requires placing each hole precisely. The holes typically overlap by 10-15mm. This creates a continuous gap that can be shaped as needed. This method works well when regular cutting tools can’t make holes big enough or when you need to avoid vibration.

Equipment You Need

For diamond core stitch drilling, you’ll need these special tools:

- Diamond Core Bits: These drill bits have diamond coatings and come in sizes from 10mm to 1500mm. You choose the size based on your project needs.

- Drilling Rigs: These powerful drilling machines spin at 600-900 RPM. They must be stable and precise.

- Mounting Systems: These frames hold the drill steady and reduce vibration. They use vacuum or mechanical anchors to stay in place.

- Water Systems: These deliver 3-5 litres of water per minute to cool the drill bit, make it last longer, and reduce dust.

- Measuring Tools: Laser systems and digital devices ensure holes are placed exactly where needed, with accuracy of ±2mm.

How It Compares to Other Methods

Project managers should know how stitch drilling compares to other ways of making holes:

| Method | Max Opening Size | Vibration | Dust | Precision | Effect on Structure |

|---|---|---|---|---|---|

| Stitch Drilling | No limit | Very low | Low | High (±2mm) | Very low |

| Regular Core Drilling | Up to 1500mm | Low | Low | High | Low |

| Wall Sawing | Limited by blade | Medium | Medium | Medium | Medium |

| Breaking with Impact Tools | No limit | High | High | Low | High |

This comparison shows that diamond stitch drilling works best when you need large or odd-shaped openings and must keep the building strong and clean.

How Stitch Drilling is Used in Construction

Common Uses

Stitch drilling works especially well for these construction jobs:

- HVAC Systems: Making precise holes for air ducts in existing buildings.

- Utility Pathways: Creating paths for electrical wires, plumbing, and data cables through concrete with minimal damage.

- New Doorways and Windows: Making openings in walls while keeping the building strong.

- Elevator Shafts: Creating precise openings in multi-story buildings where accuracy affects safety.

- Earthquake Upgrades: Making connection points for reinforcement in seismic projects.

What to Consider for Your Project

Before using diamond core stitch drilling, project managers should check these factors:

- Building Materials: It works best on concrete, brick, and stone. The density and reinforcement will affect which drill bits to use.

- Structural Safety: Have engineers check if the hole will weaken the building. They should evaluate load paths and reinforcement needs.

- Space Requirements: Make sure there’s enough room for the drilling equipment to operate.

- Water Management: Plan how to control water runoff and slurry. Noise reduction may also be needed in some places.

- Project Schedule: Plan when drilling will happen to avoid disrupting other work.

How to Plan and Execute Stitch Drilling

Planning Steps

To use diamond stitch drilling effectively, follow these planning steps:

- Structural Check: Have engineers evaluate how the opening will affect the building and specify any reinforcement needed.

- Subsurface Scanning: Use ground-penetrating radar (GPR) to find hidden elements like cables, rebar, or conduits that might be in the way.

- Technical Specs: Create detailed plans for hole diameter, spacing, depth, and pattern based on the opening you need.

- Resource Planning: Determine what equipment, workers, and time you’ll need based on the job’s complexity.

- Risk Planning: Identify potential problems and develop backup plans.

Execution Steps

Follow these steps when performing diamond core stitch drilling:

- Site Setup: Set up water containment, dust control, and secure the work area.

- Marking: Mark the drilling pattern on the surface, showing hole centers and the opening outline with ±2mm accuracy.

- Equipment Setup: Position and secure the drilling rig according to manufacturer instructions.

- Drilling Order: Drill holes in a sequence that maintains structural stability, usually working from the center outward.

- Quality Checks: Continuously check hole alignment, depth, and overlap to ensure they meet specifications.

- Material Removal: After drilling all holes, carefully remove the cut section using hydraulic tools or lifting equipment.

- Edge Finishing: Smooth the edges by grinding, polishing, or adding edge protection.

After Completion

After finishing stitch drilling, project managers should:

- Measure: Confirm the opening meets the required dimensions.

- Inspect: Check the surrounding material for any damage that needs repair.

- Test: Verify the opening works for its intended purpose.

- Document: Keep records of the work, including measurements, photos, and any changes from the original plan.

Costs and Benefits

Cost Factors

Project managers should consider these costs for stitch drilling operations:

- Equipment: Specialized drilling equipment costs £4,000 to £20,000 per unit. Rental options cost about £400-£1,200 per day.

- Drill Bits: Diamond core bits cost £150 to £2,500 each depending on size and quality. Each bit typically drills 10-30 linear meters before wearing out.

- Labor: Skilled operators earn 15-25% more than standard construction workers. Most jobs need at least two workers.

- Time: Work progresses at 0.5 to 2 linear meters per hour, depending on material and hole size. Plan your schedule accordingly.

- Other Costs: Water management, dust control, and waste disposal add to the total cost.

Why It Might Save Money

When comparing stitch drilling to other methods, consider these benefits:

- Precision: The high accuracy often reduces the need for adjustments later, offsetting the higher initial cost.

- Structural Safety: The minimal impact on the building can reduce or eliminate costs for structural reinforcement.

- Schedule Benefits: The low noise and vibration may allow other work to continue nearby, potentially shortening the overall schedule.

- Risk Reduction: The controlled nature of the process reduces the risk of accidental damage, avoiding costly repairs.

- Long-Term Quality: Openings made with stitch drilling typically have better edge quality and stability, reducing maintenance needs.

Real-World Examples

Stitch Drilling a 3m Hole

We were asked by a client in Hampshire to stitch-drill a 3m diameter circle in the floor of their underground house.

Read our full blog post here: Stitch Drilling in Hampshire

Conclusion

Stitch drilling is an advanced solution for making openings in buildings. It offers precision, versatility, and minimal structural impact. Contractors and project managers can get better results while controlling costs by using this method.

To use it effectively, you need to understand the technical details, plan carefully, and execute precisely. Project managers who master these principles will have a valuable tool for their construction projects.

As construction technology advances, diamond stitch drilling techniques will continue to improve with better equipment, automation, and integration with digital platforms. Forward-thinking construction professionals should keep up with these developments to maintain their competitive edge.

More Information

Diamond stitch drilling – Designing Buildings the construction wiki